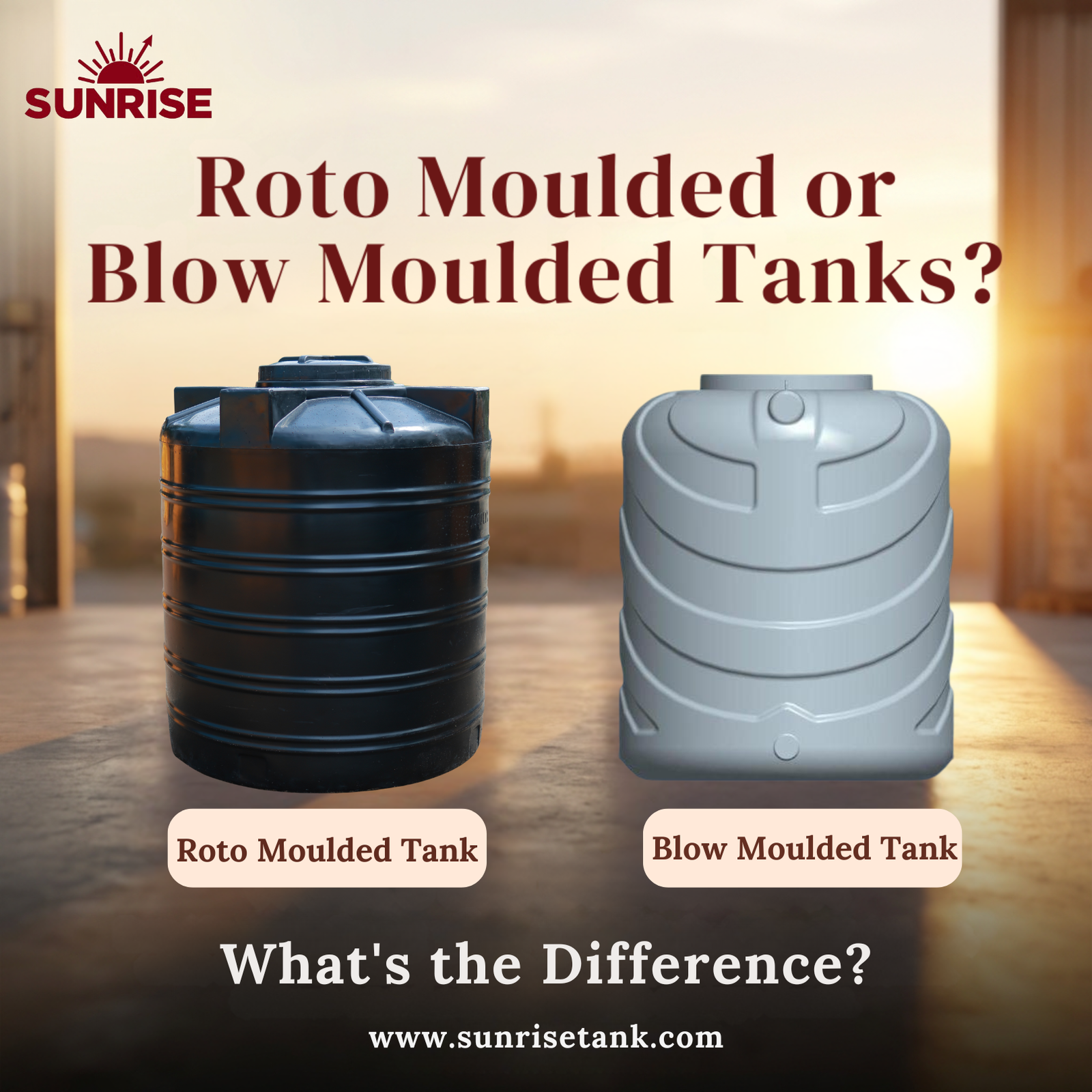

When the majority of the people imagine water tanks, they visualize a big plastic container perched on a terrace or in a yard — and they hardly even stop to think about how that tank was made. But a manufacturing technique used to create a water tank plays a very major role in its strength, durability, design, and how much it costs. Before you purchase your next water tank, it helps to figure out what is behind the scenes — notably the two major techniques used today: roto moulding and blow moulding.

Why are Manufacturing Methods So Important?

Not every plastic tank is a duplicate of the previous one. The method used to transform the plastic into a tank affects many qualities of a tank, such as how strong the tank is, how long it lasts, how it will perform under the sun, and how it holds water without leaking as well. Although most of the buyers don’t understand these terms well yet, perceiving them can help them make a smarter choice.

What Is Roto Moulding?

Roto moulding (short form of rotational moulding)is a technique wherein powdered plastic resin is placed inside an empty mould, and this mould is then rotated on two axes while it is being heated so that the plastic inside the mould melts and sticks to the walls of the mould evenly. Once the plastic cools, the solid tank is removed — usually as a single, seamless piece.

Advantages of Roto Moulded Tanks

- Seamless and Strong: As the tanks are molded into 1 piece, there are no such joints that might leak or weaken over a period of time

- Durable and Weather-Resistant: These tanks are UV-resistant and built to withstand sunlight and temperature variation, which happens a lot in India.

- Wide Range of Sizes: Tanks can be made of various shapes and capacities — from small household tanks to large farm storage to large industrial tanks.

Disadvantages of Roto Moulding

- Slow Production: Each tank can take long periods of time to produce compared to other production methods.

- Material Limitations: Only some resins that have the ability to be both powdered and heated are used.

- Higher Labor Needs: The process is not much automated, so production may be more manual, hence requiring more people.

What Is Blow Moulding?

Blow moulding is a different process wherein a tube-like piece of molten plastic, called parison, when placed in a mould, is inflated with air so that it expands and takes the shape of the mould it is placed in. Once it cools down, the tank is produced with uniform-thickness walls.

Advantages of Blow Moulded Tanks

- Fast and Efficient: Blow moulding production is much quicker, so production is faster as well.

- Uniform Wall Thickness: It helps to ensure consistent strength and structural integrity of the tank.

- Cost-Effective at Volume: Perfect choice for producing many tanks quickly.

- Lightweight and Durable: These tanks tend to be easier to handle due to being lighter in weight as compared to roto-moulded tanks, and are still strong enough for everyday use.

Disadvantages of using the Blow Moulding Technique

- Very High Tool Cost: The initial mould investment for blow moulding can be very expensive.

- Less Design Complexity: This technique cannot always produce very complex shapes.

- Limited Thickness: It can be harder to make very thick-walled products.

- Can break easily: Since the tank after production is joined on the sides, there is a possibility it might break off in case of very high pressure of water, as compared to roto-molded tanks that are joined on top.

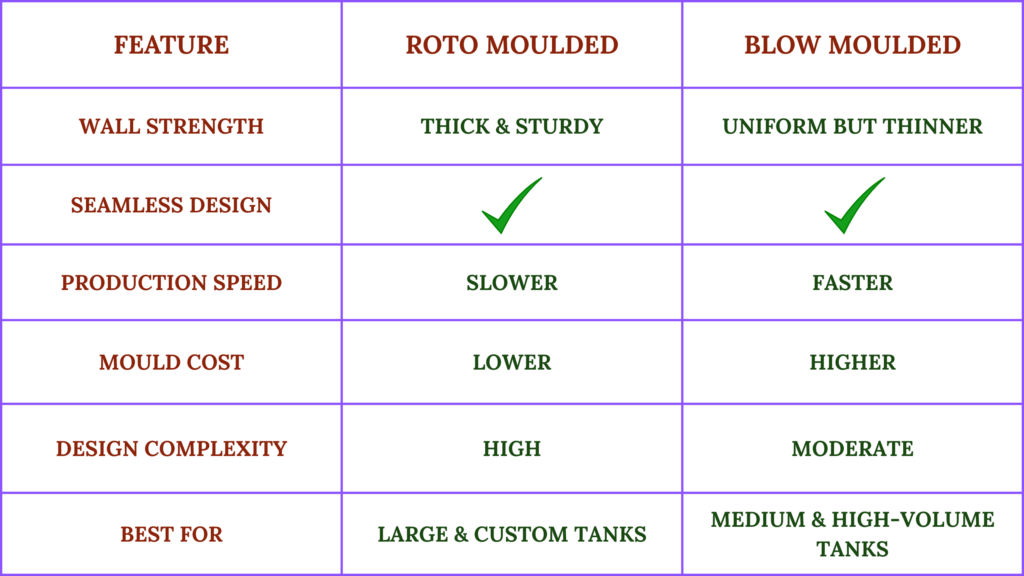

Difference between Roto Moulding & Blow Moulding Techniques!

Roto Mould vs Blow Mould: Comparison

Choosing between the two tanks made using different techniques generally depends on what the tank will be used for — whether it will be used as a large storage solution for a farm or as a standard rooftop tank for one’s home.

Sunrise Tanks by Rajaram Polymers: A Real Example

Sunrise Tanks by Rajaram Polymers is one such brand that offers consumers in Koteshwar, Udupi, Karnataka, and the nearby areas dependable and long-lasting water storage solutions. Sunrise water tanks are produced with a smooth, single-piece manufacturing technique that improves strength, durability, and long-term performance through the use of an innovative roto molding technology.

With more than 18 years of plastic manufacturing experience, Sunrise provides a huge selection of water tanks in various capacities, ranging from 200 to 5000 liters. These tanks can be used for commercial, residential, or agricultural purposes. These tanks’ consistent wall thickness, increased resilience to cracks, and enhanced endurance in harsh weather are all made possible by the use of roto molding, which is crucial in a nation like India.

Sunrise Tanks are crafted with authentic characteristics, including UV shielding, multi-layer construction, and straightforward upkeep, establishing them as a dependable and credible option for routine water storage. By adopting the rotational moulding process, Sunrise’s main focus is on delivering tanks that balance strength, hygiene, and long-term reliability for Indian households as well as businesses alike.

Which Tank Is Right for You?

Now that you are aware of the differences between the two most used techniques to make water tanks, i.e., rotational moulding and blow moulding — and how brands like Sunrise Tanks apply these techniques in their products in reality — it now comes down to one’s own priorities.

👉 When you choose a water tank, what matters more to you — long-term durability, manufacturing technique, cost, or its overall reliability? Let us know about your thoughts and experiences in the comments below!